About DEFORM

DEFORM is an engineering software system used to analyze complex materials processes including forming, heat treatment, cutting, machining and mechanical joining. DEFORM is based on a very sophisticated nonlinear transient FEM solver with fully automatic and optimized meshing.

DEFORM provides a virtual trial run environment that allows production testing on the computer, rather than the shop floor. With its roots in metal forming, DEFORM is very strong in forging, heading, extrusion, drawing, upsetting and rolling. Users predict die fill, forming load, defects, grain flow and other critical parameters without the time and cost of hard tooling. Testing various preform designs or billet sizes is possible within hours.

Use of advanced die stress analysis has saved companies millions of dollars in tooling costs by identifying the root cause of failures. Companies use DEFORM to design tools with longer life by engineering them with a lower stress.

DEFORM is the most widely-used metal forming and heat treatment simulation system in the world. Hundreds of companies, ranging from large multi-national corporations to small family owned businesses, rely on DEFORM throughout the design and development process.

Why Simulation?

Forging design and development have been based on experience and “trial and error”. Expertise can take years to develop. Processes end up acceptable rather than optimum. Time to market is slow for challenging parts, new materials and aggressive processes.

Simulation provides a ‘virtual’ trial run prior to making tools and forging trial parts. Part development is accelerated, development cost is reduced, and optimum processes can be developed with fewer shop trials. Troubleshooting problem jobs becomes far more objective.

Why DEFORM?

DEFORM is the leading metal forming, heat treatment and machining code worldwide, with a very impressive user base. Companies ranging from small forge shops to large research centers use DEFORM to optimize their processes, solve their problems, and save time and money.

Below are three typical examples of how DEFORM is used by customers.

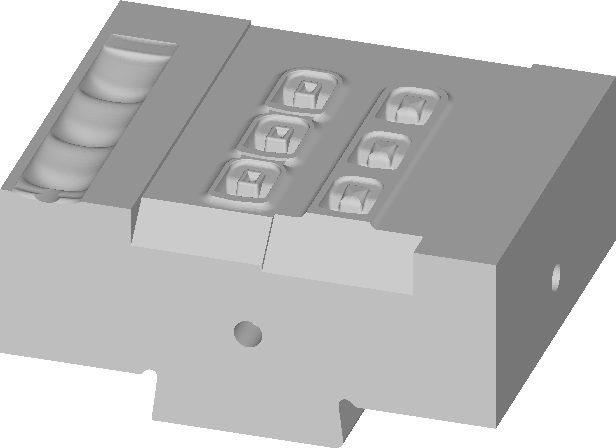

Fold Elimination

Defects (shown in red)

Final forging without defects

Weeks of lead time eliminated

Saved six trial runs

Courtesy: FDMC & Consolidated Industries

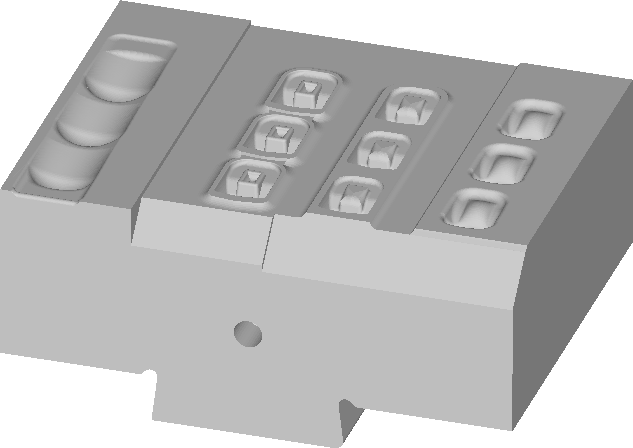

Process Design

5 roll hits

No preform operation

Part-to-part irregularities

11% scrap rate

2 roll hits

Preform operation

Process robustness improved

3.4% scrap rate

Courtesy: FDMC

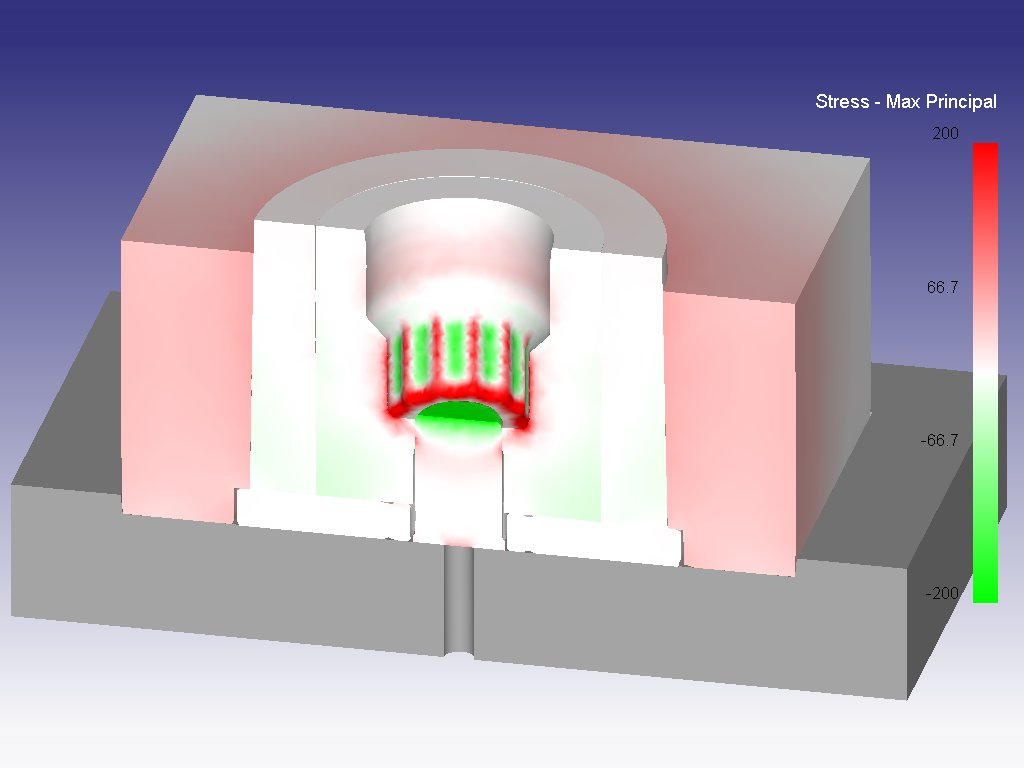

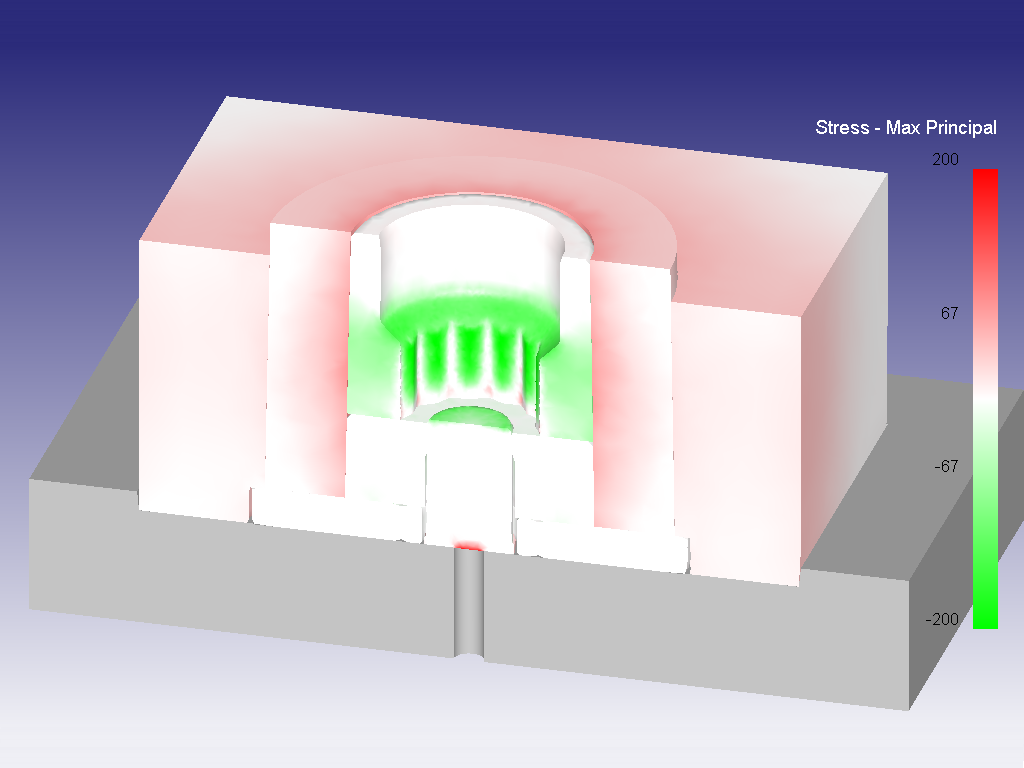

Die Cracking

Die fractured in < 10 parts

Tensile stress (red) root cause

Die did not fracture

Negligible tensile stress

Courtesy: FDMC & TECT